2019 – 2023

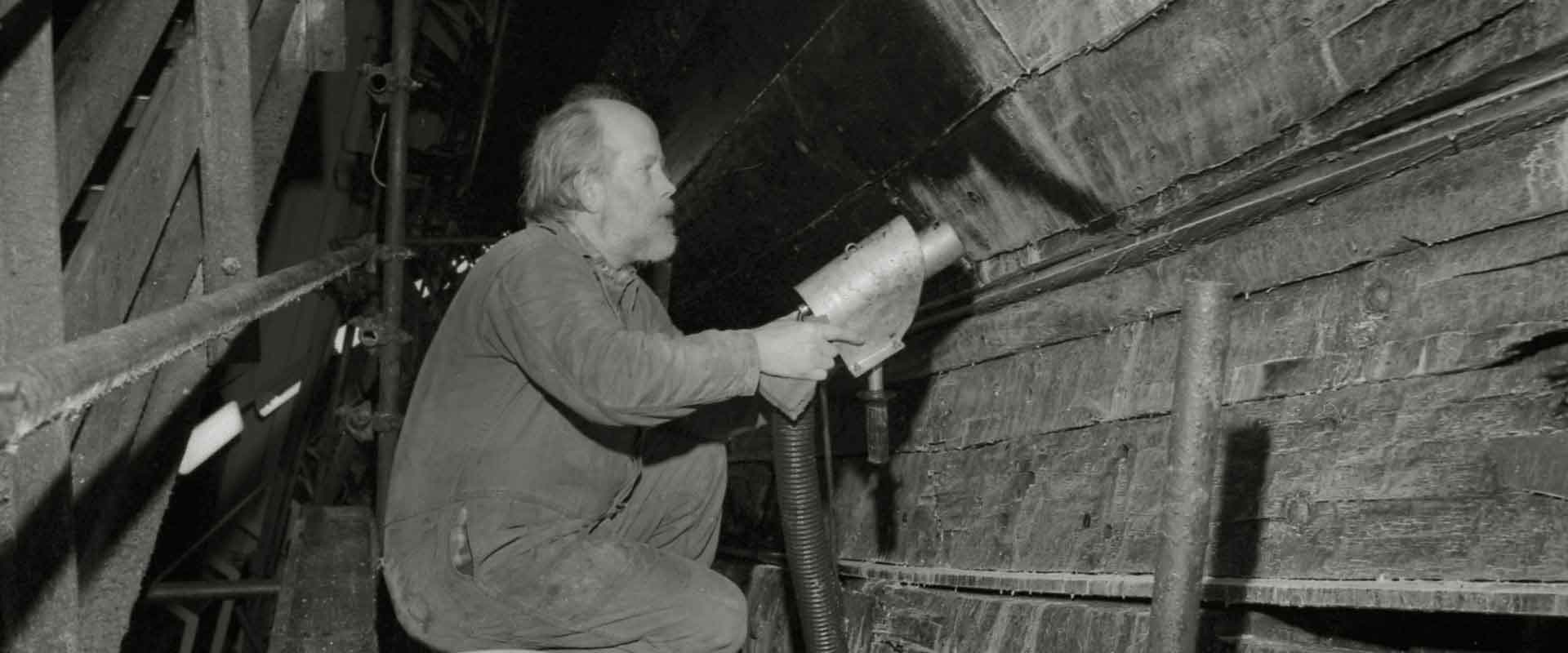

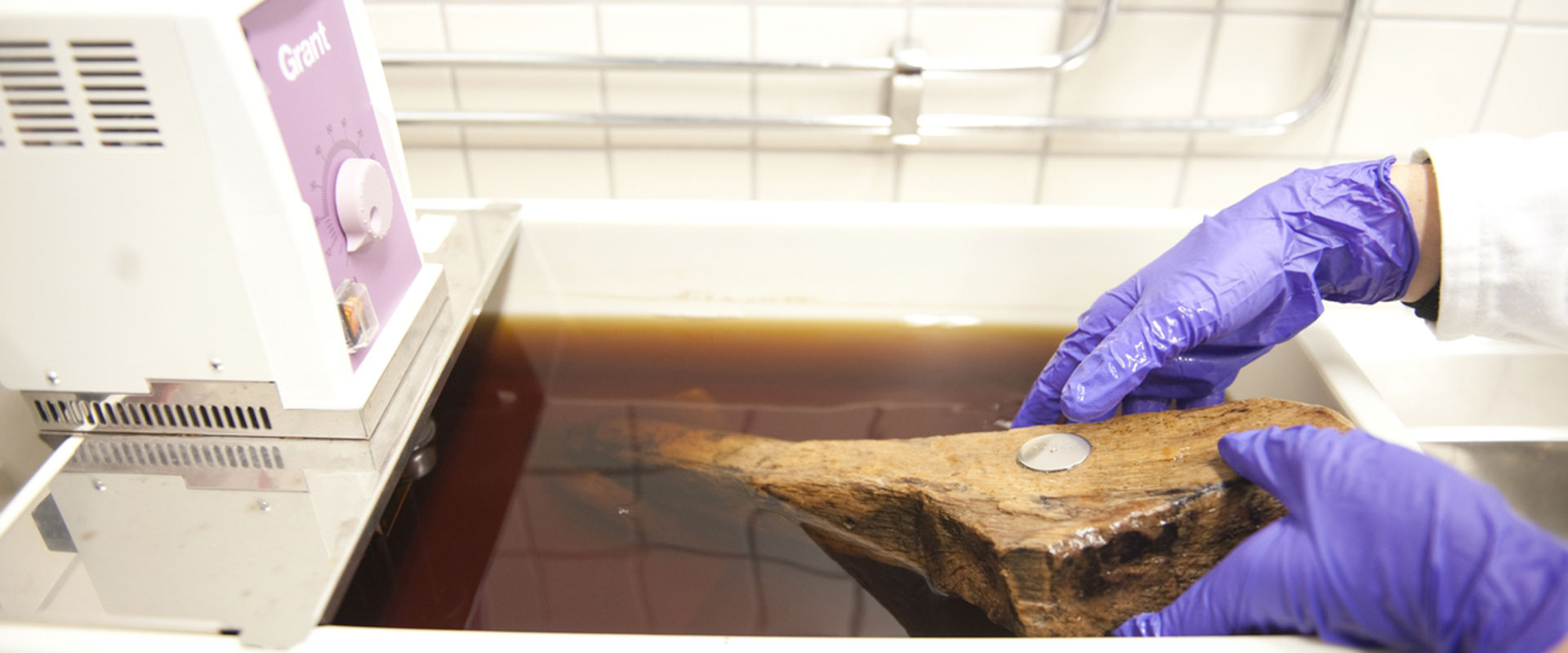

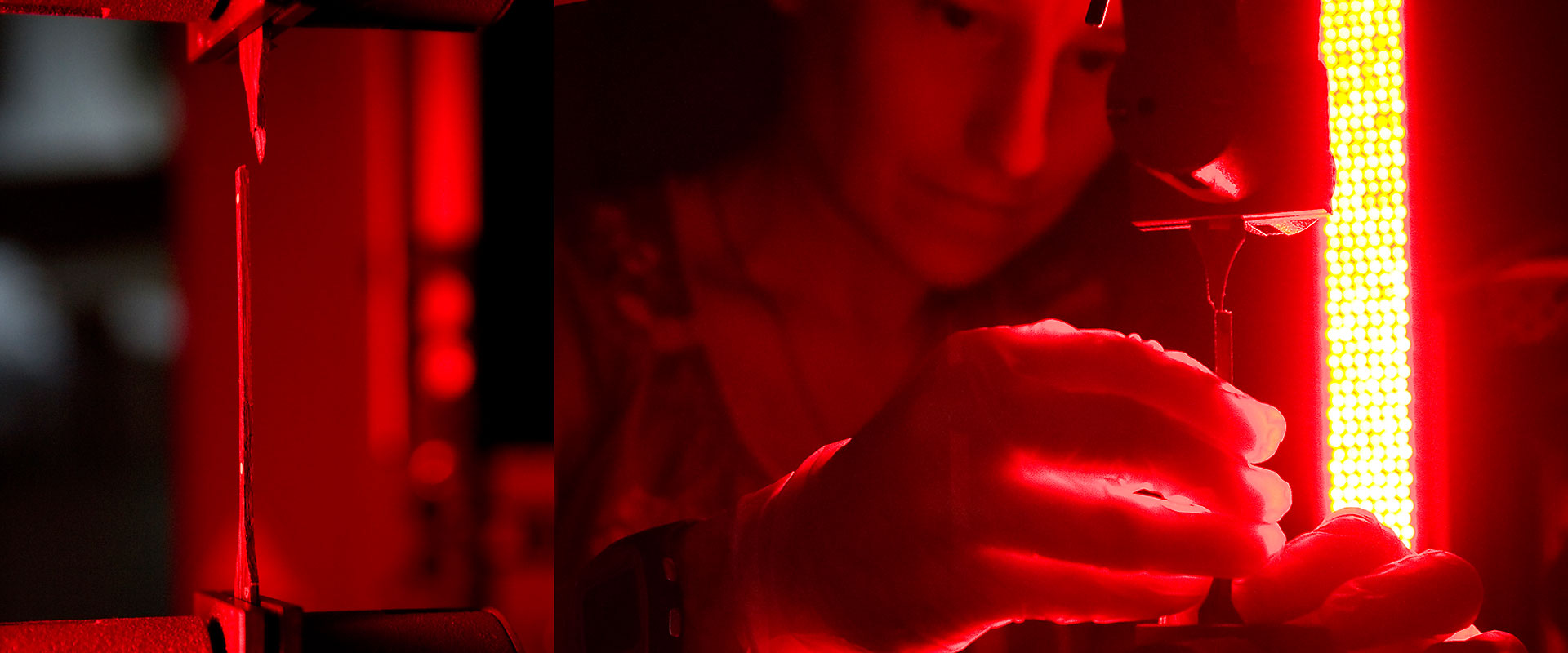

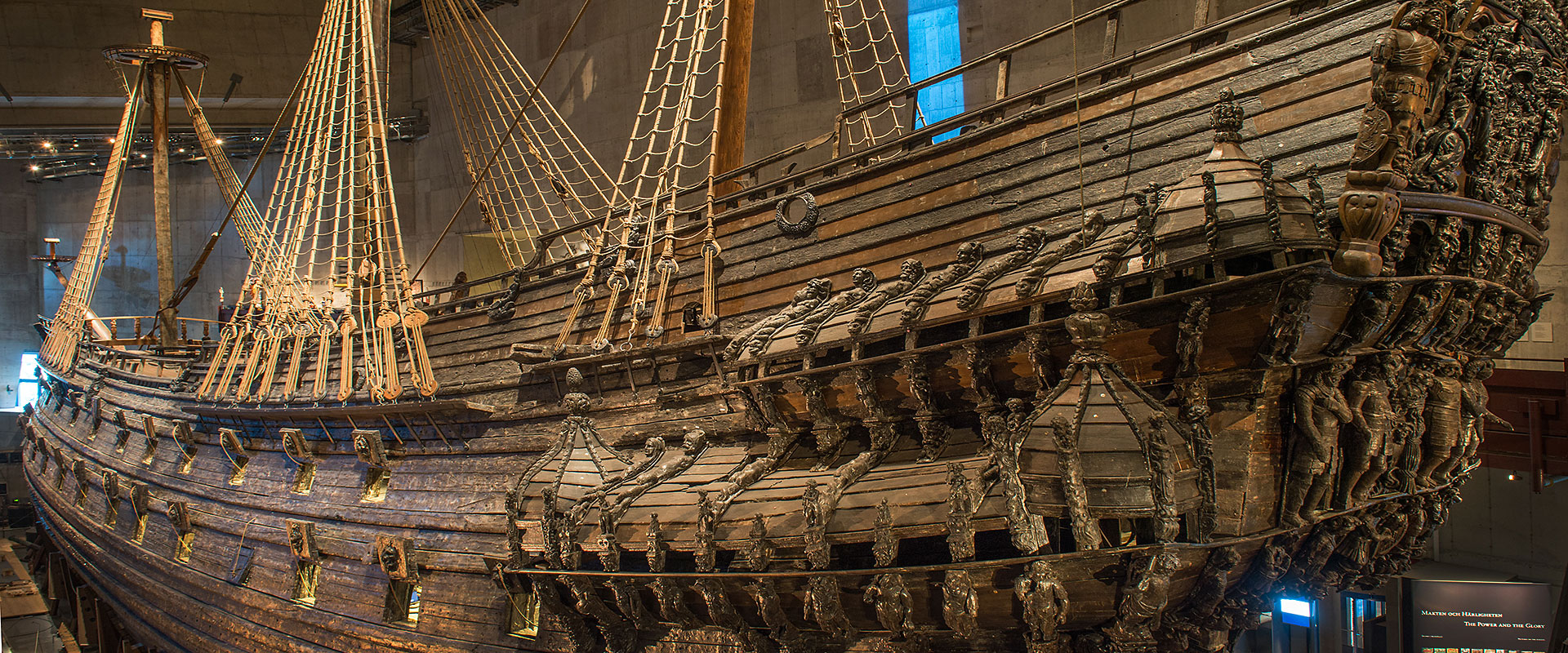

Work to design the new support structure is in progress. Because of the poor condition of the wood, samples must be taken and many tests conducted to make sure that Vasa will have the best possible support in the future.

Instead of 17 pairs of external cradle elements, Vasa will in the future have 27, along with an internal support structure that will slow down movements in the hull. Both the internal and the external support will be made of steel. The design work takes place in 2019 and 2020. The greatest challenge lies in supporting the ship’s bow and stern. The high sterncastle in particular is causing the designers a lot of headaches because the wood is heavily degraded and the aftercastle itself was fragile even when newly built.

In 2021, design drawings for the new support structure begin to be made. In 2023, the very first keel block under Vasa is replaced as a test before installation of the new support structure. Various padding materials that will lie against the ship’s hull also undergo testing.

At the end of 2023, the Vasa Museum launches a fundraising campaign to help cover the costs of the new support structure. The target group of the campaign is the general public, donors and sponsors.

Due to the difficult financial situation caused by the coronavirus pandemic, installation of the new support structure is delayed until April 2024.

Scroll down

Continue to 2024 – 2028